Table of Contents

Commercial Kitchen Flooring

Slips and trips account for around 30% of all workplace injuries in the food and drink industries. That’s a staggering figure that highlights just how crucial your flooring choice really is.

Your commercial kitchen flooring directly affects staff safety, how smoothly your kitchen runs, and whether you’ll meet hygiene compliance standards. Kitchens are high-energy, high-risk spaces where the wrong floor can spell disaster – think accidents, endless maintenance issues, and regulatory headaches. Choose wisely, though, and you can slash your slip risk to one in a million for the floor’s entire lifetime, whilst keeping your kitchen spotlessly hygienic and easy to maintain.

What makes the best commercial kitchen floors stand out? They deliver exceptional slip resistance, rock-solid durability, and effortless cleanability. Materials like polyurethane screed, vinyl, and epoxy all tick these essential boxes, though each shines in different situations. PMMA resin flooring takes things up a notch – it’s 98% cleaner than standard PU floors and delivers brilliant anti-slip properties too.

Don’t just focus on what you’ll pay upfront when selecting non-slip commercial kitchen flooring. You’ll want to think about long-term maintenance needs and how long the floor will actually last. Quality commercial kitchen floor materials can serve you faithfully for up to 30 years with proper care, dramatically cutting your total ownership costs and minimising workplace disruption.

Comparing Commercial Kitchen Flooring Materials

Selecting the right commercial kitchen flooring means getting to grips with how different materials actually perform when the kitchen gets busy. Let’s examine how the three main options stack up against each other in terms of performance, durability and day-to-day practicality.

Resin Flooring Types: PMMA vs PU vs Epoxy

Resin flooring has become a go-to choice for commercial kitchens because of its seamless surface and brilliant resistance to chemicals, heavy traffic, and wild temperature swings. Not all resins are created equal, though.

PMMA (Polymethyl Methacrylate) resin delivers some serious advantages over other types. It’s certified to the highest standards of both Food Conformity (EN1186) and Slip Resistance (BS7976-2:2002). What really sets it apart is that lightning-fast cure time—hardening within just 1 hour—which means minimal kitchen downtime during installation. PMMA creates a seamless, monolithic surface that stops bacteria in its tracks and can handle extreme temperature variations without cracking or lifting.

Polyurethane (PU) resin brings excellent impact and abrasion resistance thanks to its flexibility. This makes it a solid choice for areas that experience temperature fluctuations. The downside? PU resin demands considerably longer curing times—typically 3-5 hours to dry and 3-5 days to fully cure. Kitchen operations face extended disruption during installation.

Epoxy resin, popular as it is for chemical resistance, comes with several limitations for industrial kitchen flooring. It has the longest cure time of all resin types—up to 7 days—and shows greater sensitivity to high temperatures than other resins. Epoxy also tends to discolour when exposed to lactic acid, creating headaches in kitchens using dairy products.

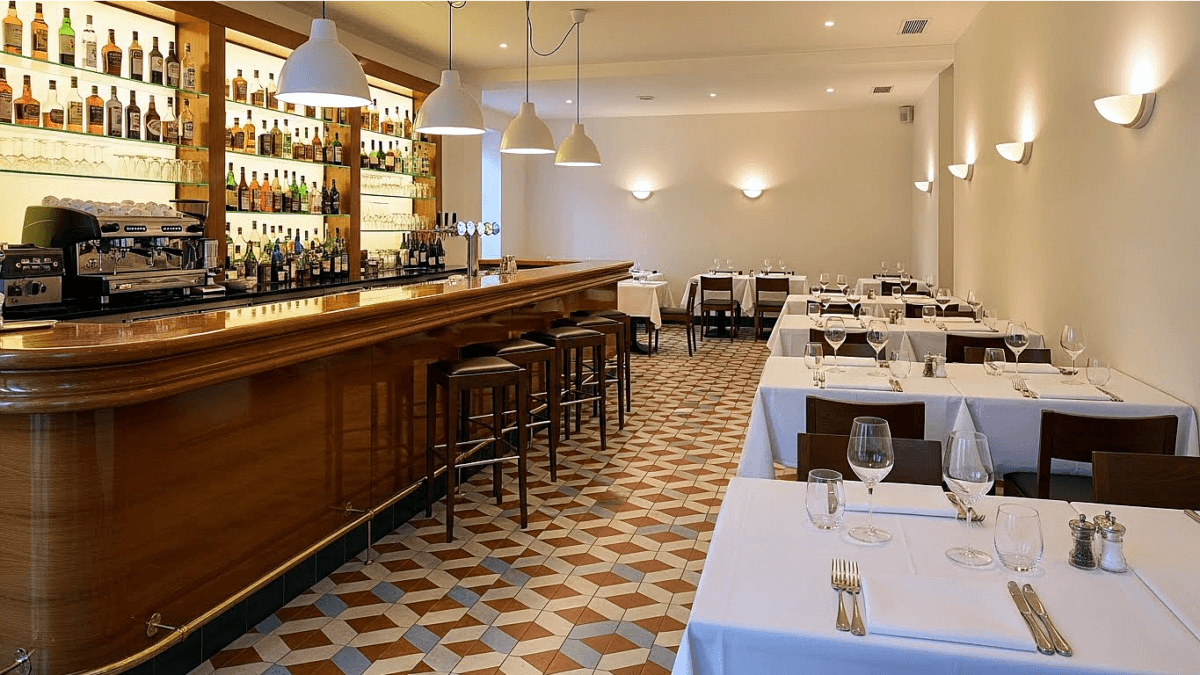

Ceramic Tile Flooring: Aesthetic vs Practicality

Ceramic tiles remain a popular commercial kitchen floor option, particularly loved for their aesthetic qualities and heat resistance. They offer stain, heat, and water resistance, making them potentially suitable for certain kitchen areas. Their decorative potential makes them especially appealing for open kitchens visible to customers.

These benefits come with significant practical challenges, though. The grout lines between tiles create hygiene risks by harbouring bacteria over time. These grout lines prove extremely difficult to clean thoroughly and can deteriorate rapidly in high-moisture environments. Grout failure frequently leads to bacteria growth followed by complete floor failure.

Installation of ceramic tiles requires specialised labour and various tools, potentially increasing installation costs by up to 50%. Despite their hardness, ceramic tiles can crack under significant impact, creating both hygiene risks and tripping hazards.

Non-slip commercial kitchen flooring presents ceramic tiles with a particular dilemma. The ridges that provide slip resistance simultaneously trap dirt and germs, making thorough cleaning a real challenge. Once a tile loses its anti-skid properties, unlike PMMA resin, it cannot be renewed—the entire floor must be replaced.

Vinyl Flooring: Cost-Effective but Short-Lived

Vinyl flooring represents the most budget-friendly option for commercial kitchen floors. Available in sheets, panels or tiles, it provides a relatively low-cost solution for creating a safe working environment. Sheet vinyl particularly minimises joins, reducing opportunities for dirt accumulation. Vinyl also offers comfort underfoot for staff who must stand for long periods.

Vinyl flooring proves unsuitable for long-term use in demanding kitchen environments, however. It cannot be repaired—any damage requires complete floor replacement. Vinyl is highly vulnerable to heat, moisture, and sharp objects, making it inappropriate for areas near fryers, ovens, or dish stations.

Maintenance presents another significant challenge. Many vinyl flooring options will discolour after repeated cleaning due to dirt becoming trapped under the wax layer. Contact with rubber (from mats or shoes) can cause permanent marks. Under high-traffic conditions in commercial kitchens, vinyl typically requires replacement within 3-7 years.

The best commercial kitchen flooring ultimately depends on your specific needs, but PMMA resin typically offers the optimal balance of hygiene, durability, and repair potential for demanding commercial kitchen environments.

Hygiene and Anti-Slip Performance in Industrial Kitchens

Safety inspection officials often flag kitchen floors that feel slippery as a major workplace hazard. Floors with poor slip resistance can cause serious accidents, especially where water and grease create treacherous conditions.

PMMA Resin: EN1186 and BS7976-2:2002 Certified

Why does PMMA resin flooring perform so brilliantly in commercial kitchen floors? It’s certified to the highest standards for both food safety and slip resistance – Food Conformity (EN1186) for hygiene and Slip Resistance (BS7976-2:2002). This dual certification proves crucial for commercial kitchens that must comply with strict health and safety regulations.

The seamless, monolithic surface creates a non-porous barrier with exceptional cleanliness levels. This was confirmed in a real-world case at Dairygold’s milk processing facility, where swab testing showed PMMA flooring performed beyond expectations – achieving cleanliness results typically expected only from stainless steel surfaces.

Here’s where industrial kitchen flooring gets tricky: balancing grip with cleanability. Textured surfaces boost traction but can harbour bacteria. PMMA cleverly resolves this dilemma through anti-skid coatings that can be quickly reapplied without compromising hygiene or causing operational downtime.

Grout Contamination in Ceramic Tile Floors

Ceramic tiles themselves resist bacteria brilliantly, but the grout lines between them? That’s where problems start for commercial kitchen floor tiles. These joints typically constitute about 3% of the total floor area but create disproportionate contamination risks.

Oleic acid, produced when frying food, flows through grout lines along with oils and fats, accumulating in cavities beneath the tiles. This contamination damages tile adhesive and the substrate over time, creating perfect conditions for bacterial growth. Standard mopping or hosing removes surface contaminants whilst what’s absorbed below remains as a food source for bacteria.

Research by Campden & Chorleywood Food Research Association found that properly installed ceramic tiles with epoxy resin grouts can maintain acceptable hygiene levels. However, grout inevitably deteriorates faster than the tiles themselves in high-moisture, chemically aggressive kitchen environments.

Wax Layer Discolouration in Vinyl Surfaces

Vinyl flooring starts promisingly – offering decent anti-slip properties and appearing easy to clean, making it an appealing budget-friendly option for commercial kitchen flooring. Its performance deteriorates rapidly under intensive kitchen conditions, though.

The transparent wax layer that provides vinyl’s initial slip resistance breaks down under constant cleaning, eventually creating hazardous conditions in wet areas. Regular exposure to cleaning chemicals leads to discolouration issues that simply cannot be fixed.

Yellowing of vinyl surfaces often signals deeper problems beneath. Trapped moisture ranks among the most common causes of this discolouration. Once moisture penetrates beneath the vinyl layer, it creates conditions perfect for mould and bacterial growth, presenting serious hygiene concerns.

The best commercial kitchen flooring should maintain both slip resistance and hygiene standards throughout its lifespan – something vinyl struggles to deliver under demanding commercial conditions.

How Well Does Your Flooring Handle the Daily Punishment?

Commercial kitchens are brutal environments for flooring. Scorching hot spills, caustic cleaning chemicals, heavy equipment being dragged around, and endless foot traffic – your commercial kitchen flooring faces this relentless assault day after day, year after year.

Heat Stress: Why PMMA Outperforms Epoxy Resin

Temperature swings between your freezer areas and cooking zones create serious stress on industrial kitchen flooring. PMMA resin flooring handles this punishment brilliantly, coping with everything from sub-zero temperatures to the heat near your ovens. Whilst PMMA’s maximum decomposition temperature sits at 360°C compared to epoxy’s 430°C, PMMA shows superior thermal shock resistance – crucial when hot trolleys get parked on the floor.

Epoxy resin struggles here, despite its decent chemical resistance. Once heat damage occurs, you’re looking at complete replacement. That means serious operational disruption because epoxy has the longest cure time of all resin options. We’re talking up to 7 days for full curing, which creates massive downtime.

The Weak Link in Ceramic Tile Systems

With commercial kitchen floor tiles, the tiles themselves rarely give you trouble. The grout lines? That’s where things fall apart. Many restaurant owners end up replacing tile grout every year or two – a significant ongoing expense that adds up quickly.

Your tile floors face extreme daily punishment plus the intense cleaning regimens that health codes demand. Grout lines deteriorate rapidly under these conditions, especially when exposed to no-rinse cleaners. Once grout starts failing, you get:

- Oils, grease and food particles seeping through

- Bacteria thriving in cracks and porous areas

- Structural damage to the substrate below

- Complete floor failure requiring total replacement

Even industrial-grade epoxy grout, which resists chemicals better, develops fractures over time that create contamination pathways.

Vinyl’s Achilles’ Heel: Substrate Problems

Best commercial kitchen flooring needs to work with whatever lies beneath it. Vinyl flooring might seem attractive budget-wise, but it’s surprisingly fussy about substrate conditions. Bumps and irregular surfaces cause uneven wear, and small debris pieces can actually tear through the vinyl.

Temperature sensitivity makes things worse. Heat and temperature fluctuations cause vinyl to expand and contract, creating unsightly tenting and gaps at edges. This becomes a real problem near cooking equipment or anywhere direct sunlight hits.

These substrate and temperature vulnerabilities make vinyl unsuitable for busy commercial kitchen floors. Even relatively quickly, these weaknesses lead to premature failure and replacement headaches.

Installation and Repair Considerations

Installation and repair factors can make or break your commercial kitchen flooring decision. After all, what’s the point of perfect flooring if installing it shuts down your kitchen for days?

1-Hour Cure Time Changes Everything with PMMA Resin

Here’s where PMMA resin flooring truly shines – its lightning-fast cure time. Whilst traditional resin systems leave you waiting around, PMMA reaches full chemical cure within 1-2 hours, so your kitchen operations can restart almost immediately. Need repairs done? You can sort them overnight with barely any disruption to your business. If your kitchen can’t afford to stay closed for long periods, this becomes a game-changer.

Some PMMA systems are even faster – fully cured within just two hours of installation. For operations that simply can’t tolerate lengthy downtime, this means you can get installations completed within impossibly tight windows.

Ceramic Tiles Demand Specialist Skills and Time

Installing ceramic commercial kitchen floor tiles isn’t a DIY job. You’ll need qualified contractors with proper skills and specialist equipment. The whole process involves multiple stages: substrate preparation, layout planning, isolation membrane application, tile installation, and grouting. Even with a skilled crew, expect installation to take anywhere from one to three days depending on your kitchen size.

The waiting doesn’t stop there either. You’ll need at least 24 hours before allowing light foot traffic, and even longer before repositioning heavy equipment. For busy commercial kitchens, this extended timeline creates real operational headaches.

Vinyl’s Fatal Flaw: No Repair Options

The biggest problem with vinyl industrial kitchen flooring? Once it’s damaged, your only option is complete replacement. For kitchens watching every penny, this limitation can be devastating.

Sure, you can try vinyl repair kits for minor scratches, but they rarely deliver satisfactory results in high-traffic commercial kitchen floors. Even when repairs seem to work initially, they typically fail under commercial kitchen conditions. Plus, adhesive repairs need at least 24 hours to cure properly before the area can handle normal use – meaning you’re still facing operational disruption, just for a temporary fix.

Best Use Cases for Each Flooring Type

Matching the right flooring material to your specific kitchen environment ensures you get optimal performance and real value for money. Each flooring option has its sweet spot based on what it does best.

PMMA Resin for High-Performance Commercial Kitchens

PMMA resin flooring absolutely excels in demanding kitchen environments where you need the highest standards of hygiene and durability. Certified to the top levels of Food Conformity (EN1186) and Slip Resistance (BS7976-2:2002), it creates an impermeable seal that protects against bacteria. Perfect for food production facilities, high-volume restaurants, and industrial kitchens where you’re dealing with extreme temperatures and heavy equipment on a daily basis. Its brilliant resistance to water, oils and chemicals makes it spot-on for areas near fryers and washing stations. The Food Standards Agency actually recommends PMMA for establishments where food safety compliance is absolutely critical.

Ceramic Tiles in Low-Moisture Prep Areas

Ceramic tiles work beautifully in preparation areas with minimal moisture exposure and moderate foot traffic. They’re generally considered ideal for walls, backsplashes, and some flooring applications in less intensive kitchen zones. Their excellent heat resistance makes them suitable for areas next to ovens and cooking equipment. Ceramic really shines in prep areas, dining sections, and entryways where you want aesthetic appeal alongside functionality.

Vinyl Flooring in Budget-Constrained Cafeterias

Vinyl flooring serves as a practical solution for cafeterias and food service areas working with limited budgets. Fast-food establishments, bakeries, and school cafeterias typically benefit from vinyl’s affordability and straightforward installation. Its comfort underfoot makes it suitable for areas where staff spend long periods standing. Vinyl performs adequately in settings with controlled moisture levels and moderate foot traffic, offering 15-20 years of service when you maintain it properly.

Conclusion

Choosing the right commercial kitchen flooring affects safety, hygiene standards, and how efficiently your kitchen runs. We’ve explored how different materials handle the tough conditions of busy kitchens, and the differences are striking.

PMMA resin emerges as the clear winner for high-performance environments. That one-hour cure time, seamless surface, and dual certification for food safety and slip resistance make it invaluable when you can’t afford extended downtime yet need to maintain impeccable hygiene standards.

Ceramic tiles might look appealing and resist heat well, but those grout lines create real problems. They harbour bacteria and break down quickly under kitchen conditions, eventually causing complete floor failure despite the tiles themselves lasting well.

Vinyl flooring gives you a budget-friendly option, but comes with serious limitations. Short lifespan, vulnerability to heat and moisture, and no repair possibilities mean it only works for less demanding environments with moderate traffic and controlled moisture levels.

Think about total cost of ownership rather than just upfront expenses when you make your decision. Premium solutions like PMMA resin need higher initial investment but deliver superior longevity, safety features, and maintenance benefits that slash long-term costs significantly.

Your specific kitchen needs will determine which option serves you best. High-volume restaurants and industrial kitchens get the most from PMMA resin, ceramic tiles work well enough in dry prep areas, and vinyl might do the job for budget-constrained cafeterias. Choose the right material for your particular situation, and you’ll create a safer, more efficient kitchen environment that stays compliant with health regulations whilst supporting your operational goals.

Key Takeaways

Selecting the right commercial kitchen flooring is crucial for safety, hygiene compliance, and operational efficiency. Here are the essential insights for making an informed decision:

• PMMA resin offers superior performance – 98% cleaner than standard floors, certified for food safety (EN1186) and slip resistance (BS7976-2:2002), with rapid 1-hour cure time

• Ceramic tiles create hygiene risks – Grout lines harbour bacteria and deteriorate rapidly, requiring frequent replacement despite the tiles’ durability

• Vinyl flooring lacks repairability – Cannot be repaired when damaged, requiring complete replacement, making it unsuitable for high-traffic commercial environments

• Consider total ownership costs – Premium materials like PMMA may cost more initially but deliver 30-year lifespans versus vinyl’s 3-7 years

• Match flooring to kitchen demands – High-volume restaurants need PMMA resin, dry prep areas can use ceramic tiles, budget cafeterias may suit vinyl

The key is balancing upfront investment with long-term performance. Quality flooring reduces slip risks to one in a million whilst maintaining hygiene standards that protect both staff safety and regulatory compliance.

FAQs

Q1. What is the most suitable flooring material for a commercial kitchen? PMMA resin flooring is often considered the best option for high-performance commercial kitchens. It offers superior hygiene, durability, and slip resistance, making it ideal for demanding kitchen environments.

Q2. How long does commercial kitchen flooring typically last? The lifespan of commercial kitchen flooring varies depending on the material. High-quality options like PMMA resin can last up to 30 years with proper maintenance, while budget-friendly alternatives like vinyl may need replacement within 3-7 years.

Q3. Are ceramic tiles a good choice for commercial kitchen floors? Ceramic tiles can be suitable for certain areas of a commercial kitchen, particularly in low-moisture prep areas. However, their grout lines can harbour bacteria and deteriorate quickly, potentially leading to hygiene issues and floor failure over time.

Q4. How important is slip resistance in commercial kitchen flooring? Slip resistance is crucial in commercial kitchen flooring to ensure staff safety. The best flooring options, such as PMMA resin, are certified for slip resistance and can reduce the chance of slips to one in a million for the floor’s lifetime.

Q5. What factors should be considered when choosing commercial kitchen flooring? When selecting commercial kitchen flooring, consider factors such as durability, hygiene standards, slip resistance, ease of cleaning, installation time, repair options, and total cost of ownership. The specific demands of your kitchen environment should guide your choice.